Apex Glock Extractor (G-FRE) Fitting

The Apex FRE-G was designed as a close tolerance drop in part. Due to tolerance variations from slide to slide, minor adjustment may be necessary. As a safety precaution, ensure that the firearm is unloaded. After removing the original extractor from the pistol, check for any carbon build-up or debris that may have accumulated between the extractor and the extractor channel of the slide. Excess fouling between the slide and the extractor fitting pad can affect proper fit.

After installation, the first step is to check for proper tensioning against a cartridge. With the slide removed from the frame, insert an empty case or dummy round underneath the extractor claw from the bottom of the slide. You should feel slight resistance as the case moves the limiting tab of the extractor’s engagement surface out of the way. Once the resistance is overcome, there should be some measurable tension being applied by the extractor’s vertical engagement edge to the cartridge. A dummy round should remain suspended by the inward force of the extractor.

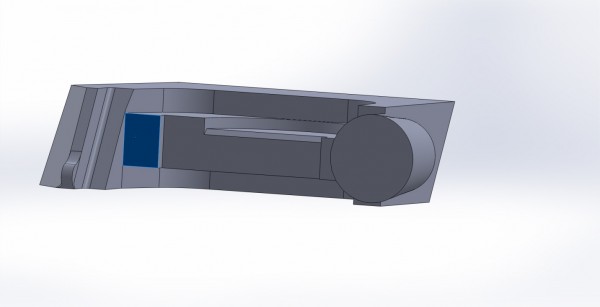

If you feel no contact between the case and the extractor, some material will need to be removed from the fitting pad located in the picture below:

If you feel no contact between the case and the extractor, some material will need to be removed from the fitting pad located in the picture below:

Figure 2

The fitting pad is the raised surface seen in the photo. It limits the inward travel of the extractor and bears against the milled flat surface inside the slide. The surface is raised .016 inch above the surface of the clearance cut (seen just to the right of the pointer). Remove material from the fitting pad until the claw will hold the dummy round in place. It should only require about .003”-.005” of material to obtain the desired tension. Reassemble and verify that a dummy round remain in place, even if the slide is shake lightly.

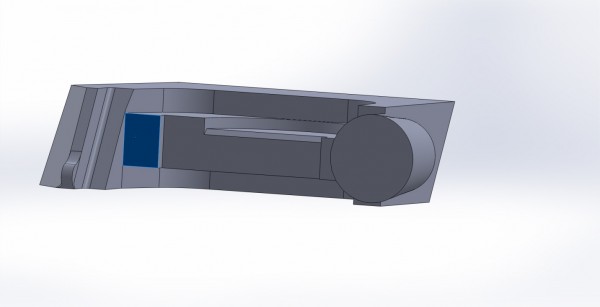

Here is another view of the fitting pad:

Figure 2

The fitting pad is the raised surface seen in the photo. It limits the inward travel of the extractor and bears against the milled flat surface inside the slide. The surface is raised .016 inch above the surface of the clearance cut (seen just to the right of the pointer). Remove material from the fitting pad until the claw will hold the dummy round in place. It should only require about .003”-.005” of material to obtain the desired tension. Reassemble and verify that a dummy round remain in place, even if the slide is shake lightly.

Here is another view of the fitting pad:

Figure 3

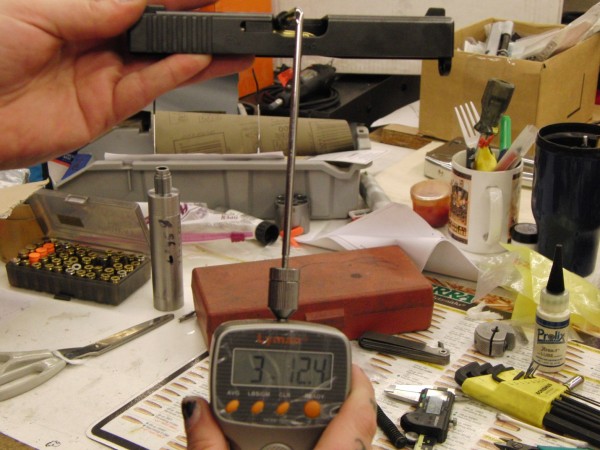

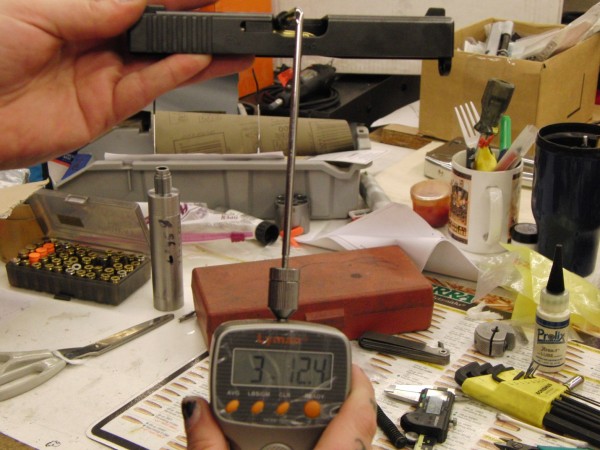

Once proper extractor tension is obtained, it is time to check proper function of the cartridge limiting tab. This is the small protrusion located at the lower edge of the extractor engagement surface. Its function is to limit the downward travel of the case as the barrel unlocks and pulls the brass from the chamber. To test this, insert a dummy round as shown in Figure 1. By pressing downward on the dummy round, noticeable force should be required before the case slips below the limiting tab and the case falls free of the extractor. It should require between 3.5-4 lbs of force before the case loses contact with the extractor. A digital trigger pull gauge can be used to measure the appropriate range of force as shown in Figure 4. The measurement of force is with the Apex extractor and spring coupled with the LCI spring loaded bearing.

Figure 3

Once proper extractor tension is obtained, it is time to check proper function of the cartridge limiting tab. This is the small protrusion located at the lower edge of the extractor engagement surface. Its function is to limit the downward travel of the case as the barrel unlocks and pulls the brass from the chamber. To test this, insert a dummy round as shown in Figure 1. By pressing downward on the dummy round, noticeable force should be required before the case slips below the limiting tab and the case falls free of the extractor. It should require between 3.5-4 lbs of force before the case loses contact with the extractor. A digital trigger pull gauge can be used to measure the appropriate range of force as shown in Figure 4. The measurement of force is with the Apex extractor and spring coupled with the LCI spring loaded bearing.

Figure 4

Figure 4

If you feel no contact between the case and the extractor, some material will need to be removed from the fitting pad located in the picture below:

If you feel no contact between the case and the extractor, some material will need to be removed from the fitting pad located in the picture below:

Figure 2

The fitting pad is the raised surface seen in the photo. It limits the inward travel of the extractor and bears against the milled flat surface inside the slide. The surface is raised .016 inch above the surface of the clearance cut (seen just to the right of the pointer). Remove material from the fitting pad until the claw will hold the dummy round in place. It should only require about .003”-.005” of material to obtain the desired tension. Reassemble and verify that a dummy round remain in place, even if the slide is shake lightly.

Here is another view of the fitting pad:

Figure 2

The fitting pad is the raised surface seen in the photo. It limits the inward travel of the extractor and bears against the milled flat surface inside the slide. The surface is raised .016 inch above the surface of the clearance cut (seen just to the right of the pointer). Remove material from the fitting pad until the claw will hold the dummy round in place. It should only require about .003”-.005” of material to obtain the desired tension. Reassemble and verify that a dummy round remain in place, even if the slide is shake lightly.

Here is another view of the fitting pad:

Figure 3

Once proper extractor tension is obtained, it is time to check proper function of the cartridge limiting tab. This is the small protrusion located at the lower edge of the extractor engagement surface. Its function is to limit the downward travel of the case as the barrel unlocks and pulls the brass from the chamber. To test this, insert a dummy round as shown in Figure 1. By pressing downward on the dummy round, noticeable force should be required before the case slips below the limiting tab and the case falls free of the extractor. It should require between 3.5-4 lbs of force before the case loses contact with the extractor. A digital trigger pull gauge can be used to measure the appropriate range of force as shown in Figure 4. The measurement of force is with the Apex extractor and spring coupled with the LCI spring loaded bearing.

Figure 3

Once proper extractor tension is obtained, it is time to check proper function of the cartridge limiting tab. This is the small protrusion located at the lower edge of the extractor engagement surface. Its function is to limit the downward travel of the case as the barrel unlocks and pulls the brass from the chamber. To test this, insert a dummy round as shown in Figure 1. By pressing downward on the dummy round, noticeable force should be required before the case slips below the limiting tab and the case falls free of the extractor. It should require between 3.5-4 lbs of force before the case loses contact with the extractor. A digital trigger pull gauge can be used to measure the appropriate range of force as shown in Figure 4. The measurement of force is with the Apex extractor and spring coupled with the LCI spring loaded bearing.

Figure 4

Figure 4